Skip to content

Resharpening Services

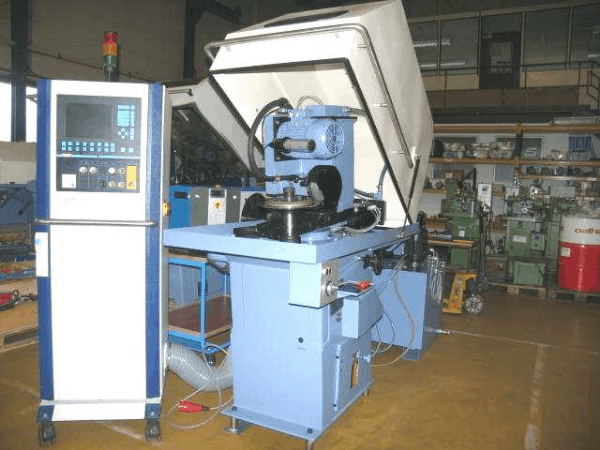

- Re-sharpening of HSS saw blades on a high-performance machine used majorly by saw manufactures only.

- Superior Gullet Finish on every gullet results in easy chip evacuation, without any clogging or built-up edges within the gullet.

- Correct various Tooth distance maintained resulting in less vibration thereby giving a smooth cut. This reduces the load on machine spindle and hence has a more machine life and less wear of the spare parts.

- Consistent Geometry of the angles in 1 and all blades, ensures higher tool life after re-sharpening, resulting in an unmatched cost per cut against the competition.

- Less Metal removal per re-sharpening ensures reduced consumption of new saw blades and higher output per blade.

- High-performance CBN grinding wheel only being used resulting in very low spark out against most of the competition that uses vitrified grinding wheels.

- Grinding with high-performance Neat Cutting oil helps in reducing grinding stress on the teeth resulting in less breakage of a tooth.

- Reports along with blades help in tracing the number of cuts in every Re-sharpening for optimum output of every blade.